Published:

January 2019

BETWEEN THE LINES

Minimizing material wastage in any production process has always been an important consideration for designers.

Material wastage does not only result in higher production costs. At times, it also limits what a client can produce to deliver the holistic experience envisioned. Therefore, a well-designed production process should not only reduce wastage, but also consider its potential.

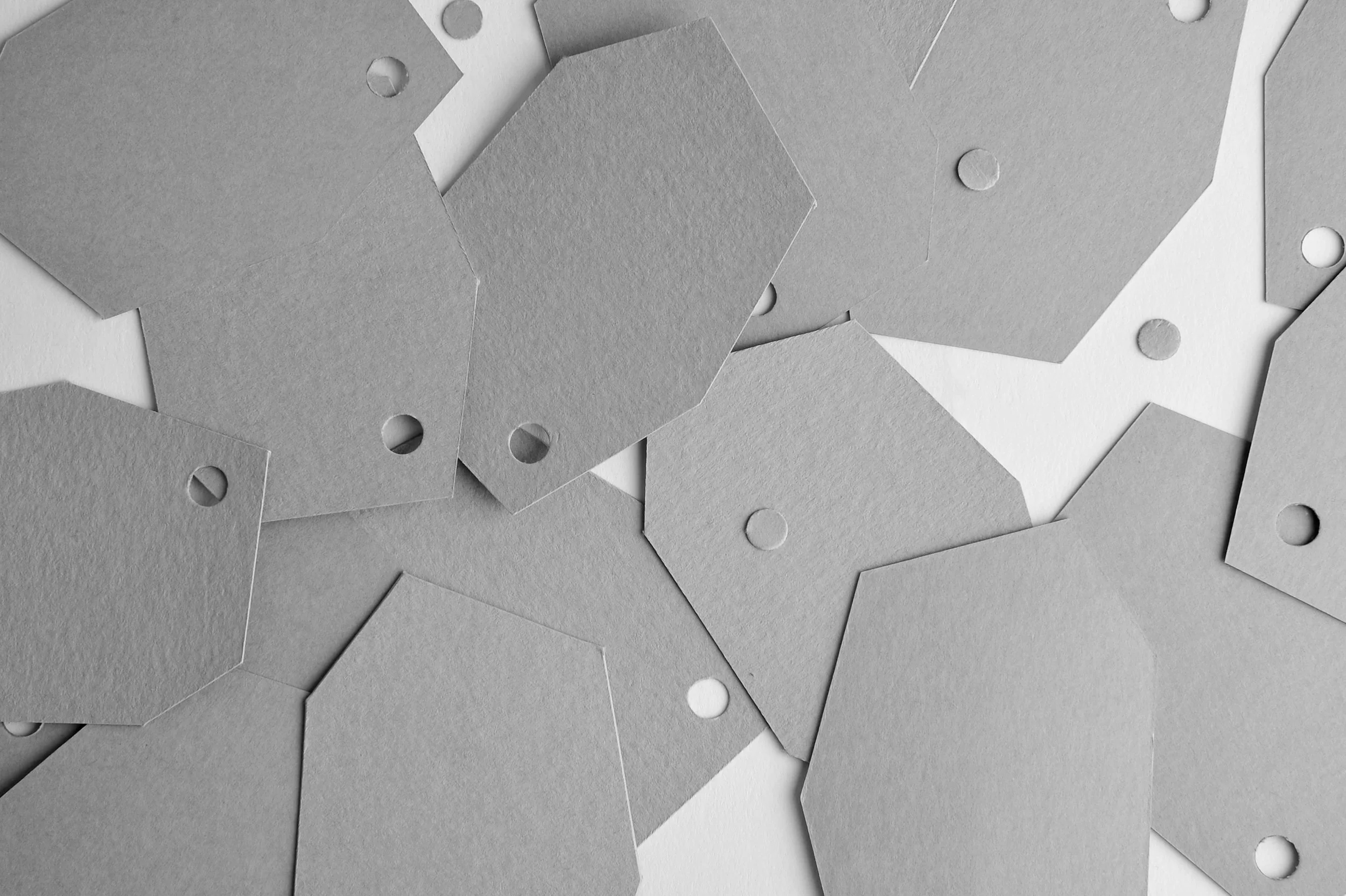

Conceived for one of our first few projects, study model HF00 (refer to Fig. A) is an accessory packaging with a cut-out window. HF00 was an attempt to utilize the cut-outs (waste) as a hang tag or a small business card (refer to Fig. B) after the die-cutting process.

Fig. A

Fig. B

Regardless of material, the act of cutting or separation is inevitable during production. Most of the time, the process separates what’s useful, from what’s not. To shift one’s mindset is to consider the fact that not everything that is separated from the primary form, equates to waste. It is not about repurposing or upcycling this waste. Rather, it is about carefully considering each element that will be separated from another, at the start of the design process.

This study model helped us discover that when a form affords more functions than expected of it or in other cases, gains new functions entirely, that a form no longer simply follows functions, but allows functions. We term such forms Hyperfunctional Forms (HF).

HF00 marked not only the beginning of our exploration of forms that Hyperfunction, but more importantly, started us thinking more deeply about some of the basic forms we often work with as designers.

view related project →